Automotive Use of Supercapacitors

Automotive manufacturers are introducing many new features which often require significant peak power or backup power support in case of power interruption. Supercapacitors can supply that power.

Supercapacitors deliver peak power to reduce size and weight

Key fob functionality is increasing, for example, to include remote climate control and encryption for improved security. This requires more power than a coin cell, such as a CR2032 cannot supply without suffering excessive voltage drop and premature shutdown. An HA102 supercapacitor is only 1.2mm thick and fits neatly over a 20mm dia. coin cell. Depending on the peak power drawn, it will enable applications that would otherwise not be possible or increase battery life by ~50%.

Supercapacitors distributed in the vehicle near the load can reduce the weight of wiring harnesses. Examples include blinkers and solenoids for door locks. In the case of blinkers, the supercapacitor can supply the peak blinker current while the wiring harness supplies only the average current = ½ the peak. This allows the cost and weight of the wiring harness to be reduced. Similarly for solenoids, where the supercapacitor supplies the peak current to drive the solenoid, but the wiring harness only need supply the charge current to the supercapacitor.

Supercapacitors can stabilise the vehicle voltage rail

The vehicle voltage rail can suffer sags, e.g. during engine cranking in stop-start operation. A supercapacitor can support the voltage rail and prevent interruptions to vehicle electronics such as the EMS, GPS, radio, etc.

Supercapacitors deliver uninterruptible power to enable graceful shutdown

Supercapacitors store significant energy with virtually unlimited cycle life. In the event of power failure they can provide backup power for essential systems allowing a safe stop, or provide power for emergency e-call. With practically unlimited cycle life a supercapacitor is a very reliable backup energy source.

APPLICATON BRIEF

AB1017 Rev 1.4

Automotive use of Supercapacitors

In the highly competitive automotive mark et auto makers are in a technology arm race. Cutting-edge innovations are appearing in every aspect of a vehicle, providing the owner with features and c onvenience they didn’t know they needed but cannot live without, as well as major improvements in safety. The move towards smaller and lighter compon ents creates challenges to power this increase in capability. CAP-XX supercapa citors’ small size, high burst power and unlimited cycle life can be the solution to bridge the gap in power delivery.

Supercapacitors in next gen car key fobs

Auto makers have been adding features to their smart car key fobs such as encryption for improved security, remote climate control and smart summon to name some examples. Having to transmit over longer distance these features require more power than the simple lock/unlock function of older car key fobs. The tiny coin cell used to power the car key will struggle with this increased demand. This either forces the car owner to change battery more frequently, which is inconvenient, or the key fob must be designed to house a larger battery. Neither is desirable. CAP-XX supercapacitors with their low ESR and ultra-thin prismatic design such as the DMF low ESR high power, DMT long life high Temperature or DMH ultra thin is a simple inclusion to increase functionality and extend the battery life.

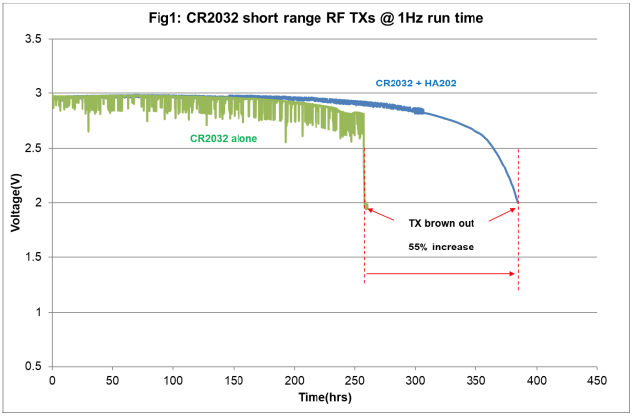

Fig 1 is an accelerated test two CR2032 batteries with and without a HA202 supercapacitor, 120mF, 120mΩ supercapacitor, running a short ranged BLE TX module. A single BLE TX draws ~15mA for around 50ms, similar to a smart key’s RF TX power. The test in Fig1 transmits once per second until module brown-out.

A typical new CR2032 battery has an internal resistance ~10Ω. As the battery is discharged, the internal resistance will increase beyond 60Ω. Drawing 15mA will drop the battery voltage to ~2V, causing the electronics to brown out, while a CR2032 battery supported with an HA202 would still be ~2.8V. This reduced voltage drop allows the BLE TX to utilise much more of the energy in the battery before brown-out, hence the 55% increase in battery life observed in Fig 1.

Reduced cabling weight with support from a supercapacitor

A modern car contains no less than 1 mile of wiring. These copper cables deliver power, deliver control and collect information throughout the vehicle. With increasing emphasis on better fuel economy, auto makers are focusing on reducing weight without sacrificing features. A supercapacitor’s low ESR and high C offsets the effect of cable impedance on supply voltage allowing thinner wire gauge to be used reducing electrical cable weight.

One system that can benefit greatly is the audio system. The high-end audio drivers responsible for the rich sound are often rated over 200W. To satisfy such a hungry load auto makers need to use much thicker power cables to eliminate harmonics from voltage variation in the supply rail due to cable impedance. CAP-XX supercapacitors’ extremely low ESR and good frequency response holds the audio driver’s supply rail steady, allowing thinner cable to be used saving significant weight while providing unparalleled audio quality.

Various electromechanical modules that provide door locking, window winding, power seat/steering wheel adjustment only require high power to overcome inertia and provide motor starting current then much lower power until the action is complete. These modules can take advantage of a built in supercapacitor to supply the high peak load and use thinner wiring only providing average power. Another example is a blinker with 50% duty cycle. A supercapacitor supplies peak blinker current while the wiring is sized for average current.

Supercapacitors Provide Voltage Stabilisation

The vehicle voltage rail can suffer sags, e.g. during engine cranking in stop-start operation. A supercapacitor can support the voltage and prevent interruptions to vehicle electronics such as the EMS, GPS, radio, etc.

Supercapacitors provide emergency power

Safety is paramount in today’s cars. Modem vehicles are all designed to have multiple system to protect the occupants. All these safety systems rely on the electrical system. Any failure in the electrical system can spell disaster. Supercapacitors can help mitigate this risk.

As well being able to provide high pulse power a supercapacitor stores significant amount of energy which can be used to power some key vehicle systems for a short time, allowing a safe stop, in the event of a failure of the electrical system. With practically unlimited cycle life, a supercapacitor is a very reliable backup energy source.

Critical safety systems such as the airbag deployment and automatic emergency responder calling system with supercapacitor power backup can save lives if the vehicle suffers an early electrical failure in an accident.

Selecting your Supercapacitor

With a 3V battery you can use a single 3V cylindrical cell, GY13R0 series, or a 2.75V prismatic cell from our H series. The HA102 and HA130 fit over a CR2032 coin cell. If using a 2.75V cell, then a low power regulator is required between the battery and supercapacitor, see Coupling a Supercapacitor with a Battery. If you are using a higher voltage battery, then a dual cell supercapacitor is required with active balancing to minimise energy drain from the battery, see the DMF, DMT or DMH series and Cell Balancing. The supercapacitor needs to have low enough ESR and high enough C at end of life to support the peak pulse load, refer to Powering Pulsed Loads. The supercapacitor, with its very low ESR may draw a large inrush current when initially charging. The battery internal impedance may be enough to limit this current, or see Current Limiting for Supercapacitors.